Looking to launch your private label clothing line? Outsourcing the clothes production to China or other low cost Southeast Asian countries has been a common practice.

By and large China has clothing wholesale markets of every scale, but is it feasible to buy wholesale clothing from China for your private label clothing line? Here we’ll explain why it seldom works.

* Size. Most sizes available are Chinese sizes.

* Labeling. You can’t customize the tags, like logo tag, washing tag, size tag, etc.

* Quality. Quality tends to be inferior.

* Language barrier. Suppliers rarely speak English or very limited.

* Limitations on customization. You can’t customize sizes, designs, choice on fabrics and accessories, manufacturing regulations not complying with the requirements of EU or other countries, etc.

Many first comers to China tend to think China’s a magic land and they can find gold, like $2 dollars a T-shirt, launching a premium quality clothing line better than Lacoste with a budget of $5000, you get what you pay for, that’s one of the basic economics.

Buying from clothes markets in China is rarely feasible unless you are willing to take all the risks.

Then how to get your private label clothes produced by a high quality clothing factory in China? There are many factors to be taken into consideration. Finding a random wholesale China cloth manufacturer online without going further like verifying supplier qualification, expertise…etc is most likely to be disastrous.

Below are some elements to take into account when choosing clothes manufacturers in China to launch your private label clothing line.

* Compliance with textile regulations in destination countries.

Some countries like Australia, the United States, Europe have strong safety standards towards imported clothing textiles, for instance, the FHSA standard used in the US has regulated substances like formaldehyde, asbestos, etc. used in the textiles.

Many Chinese clothing factories especially smaller ones even have no idea the fabric composition of the textiles, not to mention the textile regulations in other countries. It’s critical to go with high quality China clothes suppliers who are willing and able to provide fabric compliance assessment reports.

* Quality of fabrics and accessories.

Fabrics and accessories are the fundamental parts composing of a quality cloth. Before getting your hands on, you have to be clear of your fabric specification like fabric composition, weight, dying methods…etc.

In one of our articles, we wrote a guide on different types of fabrics used in manufacturing T-shirts in China.

How to Start a Private Label Clothing Line – Different Types of T-Shirt Fabrics

* Product development.

Next comes to the product development phase, which can be divided into steps.

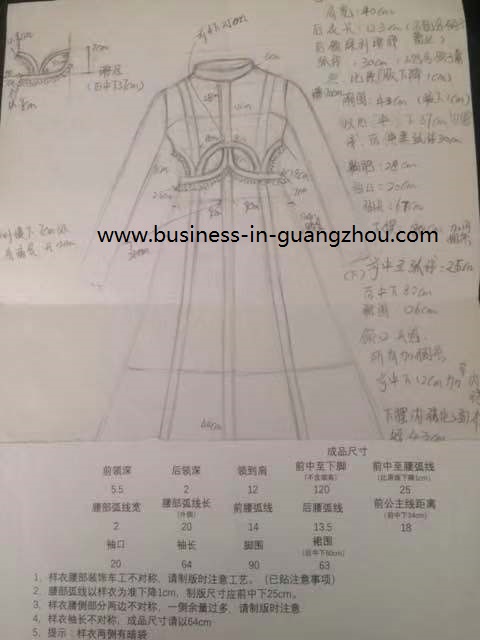

Step 1: Design/sketch.

A good design/sketch for better manufacturing quality is supposed to consists of the following elements.

# Design elements.

# Dimensions.

# Manufacturing ways (e.g. screen printing, embroidery, gold stamping).

# Fabric type (e.g. 100% cotton, 300 grams), Accessories (e.g. buttons, zippers).

# Seams.

Step 2: Prototyping.

With all sufficient information provided from Step 1, the supplier will start to make the first sample. In case you can’t provide detailed information, physical product sample is required to replicate the specification, design elements and colors. Misunderstands can occur easily if you fail to provide sufficient information, which would easily lead to poor quality of products.

If you are lucky to go with a qualified, experienced clothes manufacturer in China, you can have the first sample developed perfectly as you pictured. But normally samples take time to develop and might have to go through few revisions, and few months would have passed by if you need to ship samples for confirmation. If you are thinking about to launch your private label clothes in the coming year, it’s suggested to plan a few months ahead.

Step 3: Product Testing.

Pre-production test of fabrics and colors can help eliminate the risks of getting the mass order done in a way you don’t want.

Step 4: Manufacturing Contract.

Manufacturing Contract listing all product specifications and terms shall be signed by both parties before you pay the deposit. The main purpose of Sales Contract in China is to avoid disputes, however, in China these contracts seldom work but at least can get them taking serious of your orders. The most important thing is following closely every step of the manufacturing process and push your China clothing supplier to comply with it.

Step 5: Quality Control.

China can manufacture product of different grades in terms of quality, and quality control plays a vital role. Most China clothes factories fail to understand precision in manufacturing and quality issues are very likely to occur. But with proper management, these can be reduced or avoided.

* Labeling and packaging.

The regulations of labeling vary depending on countries, however, most countries require the label should cover country of origin (Made in China), fabric composition, washing instructions and size tags.

Packaging is not regulated but a nice package is always critical for branding purpose.

* Shipment.

There’re normally two kinds of shipment.

# By Air

Door to Door: e.g. DHL, Fedex, UPS, Aramex, etc.

Airport to Airport

# By sea.

We wrote a lot about different ways of international shipment in our previous articles. Here we just want to remind you that if you have your own courier, please ask them clearly about all the details of shipment. There’re some lessons we learnt the hard way, and hopefully you can avoid it. Take Fedex as an example, there’re Fedex Priority and Fedex Economic, one month ago we shipped 14 cartons of clothes by HK Fedex Economic to the US. We were told by the courier it would take 7-8 days. But it ended up staying in Fedex warehouse in HK for 12 days before they got them on the flight(Peak season, they have to ship all Fedex Priority first). It was fast as it arrived in 3 days in the US. But we lost credits to our client, we had no other choice as we gave them several shipping options they chose the cheapest Fedex economic, we were not told by the courier that our goods would have to queue for 12 days in the warehouse.

The next week we have the second shipment for the same client. This time we insisted shipping by DHL express to them, it costs more but the goods arrived as expected 5 days.

If you need the goods to arrive in very short time, a reliable courier is very important as some couriers tend to not tell you the hidden traps. But you get what you pay for.

Thinking about launching your private label clothing from China? Feel free to contact us as it can be quite hard to go from creating a concept to finished products. We can help you with the entire process from sketch to prototyping, quality management and shipping.

Leave a Reply